Let’s understand the Exothermic Weld Step by Step :

Follow the given Steps to do Exothermic Weld :

-

- STEP – 1: Always wear protective safety glasses and gloves while working with exothermic welding products.

- STEP – 2: Gather all the proper material and equipment/accessories for the type of connection you are making. The typical Weld system requires a graphite mould, handle clamp, welding material, natural bristle brush for mould cleaning, wire brush for cleaning/preparing conductors, flint igniter, and propane torch. Check to ensure the graphite mould is not worn or broken, which could cause leakage of molten weld metal.

- STEP – 3: Slide the handle clamp into the pre-drilled holes with the proper orientation for the thumbscrews.

- STEP – 4: Tighten the clamp thumbscrews onto the mould.

- STEP – 5: Close the grips to tightly lock the mould. Make adjustments to tighten/loosen the handle clamp.

- STEP – 6: The material to be welded (cable, rod, tape) must be clean and dry using the brush included in the set of accessories. Thus the oxide layer and superficial impurity is eliminated. Given that the graphite mould also absorbs moisture, this should be removed by preheating with a gas welding torch to avoid a porous welding. After the first welding is done, it is not necessary to re-heat the mould if the next welding is done within 15 minutes as it conserves the previously generated heat.

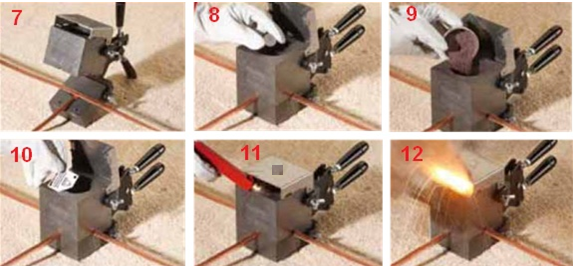

- STEP – 7: Place the conductors in the mould and close the handle clamps to avoid material leakages during the reaction.

Please Note – If there is even a minor gap between the two Conductors, apply Sealing Compound at the places where the conductors is passing out else at the time of Welding, the Powder will spread out as a flame resulting in improper joint.

- STEP – 8: Obstruct the tap hole with the metallic disk.

- STEP – 9: Empty the contents of the welding mixture package.

- STEP – 10: Empty 50% of the starting powder above Exothermic Weld Powder (Don’t Mix, just scatter) and than Close the Mould Mouth and than the rest 50% Starting Powder, Sprinkle it on the Mould Mouth nearby the small hole given on the top of the Mould Mouth.

- STEP – 11: Ignite the starting powder extended on the top/side of the mould using the flint Igniter.

- STEP – 12: Once started, the reaction will take 3-4 seconds during which it is recommended to stand clear of the mould.

- STEP – 13: After at least 2 minutes of the bonding, open the mould by undoing the handle grip. Remove the mould from the joint and clean the joint for any slag. Once open, clean the slag sticking to the mould with the relevant tool and clean the cavities. The mould will be ready now to use again without having to re-heat it as it is already warm.

Follow the given Steps to do Exothermic Welding :